Your browser version is too low, it may lead to sites not normally access!

You can use the site to function properly, use these browsers.

Your browser version is too low, it may lead to sites not normally access!

You can use the site to function properly, use these browsers.

Machine characteristics

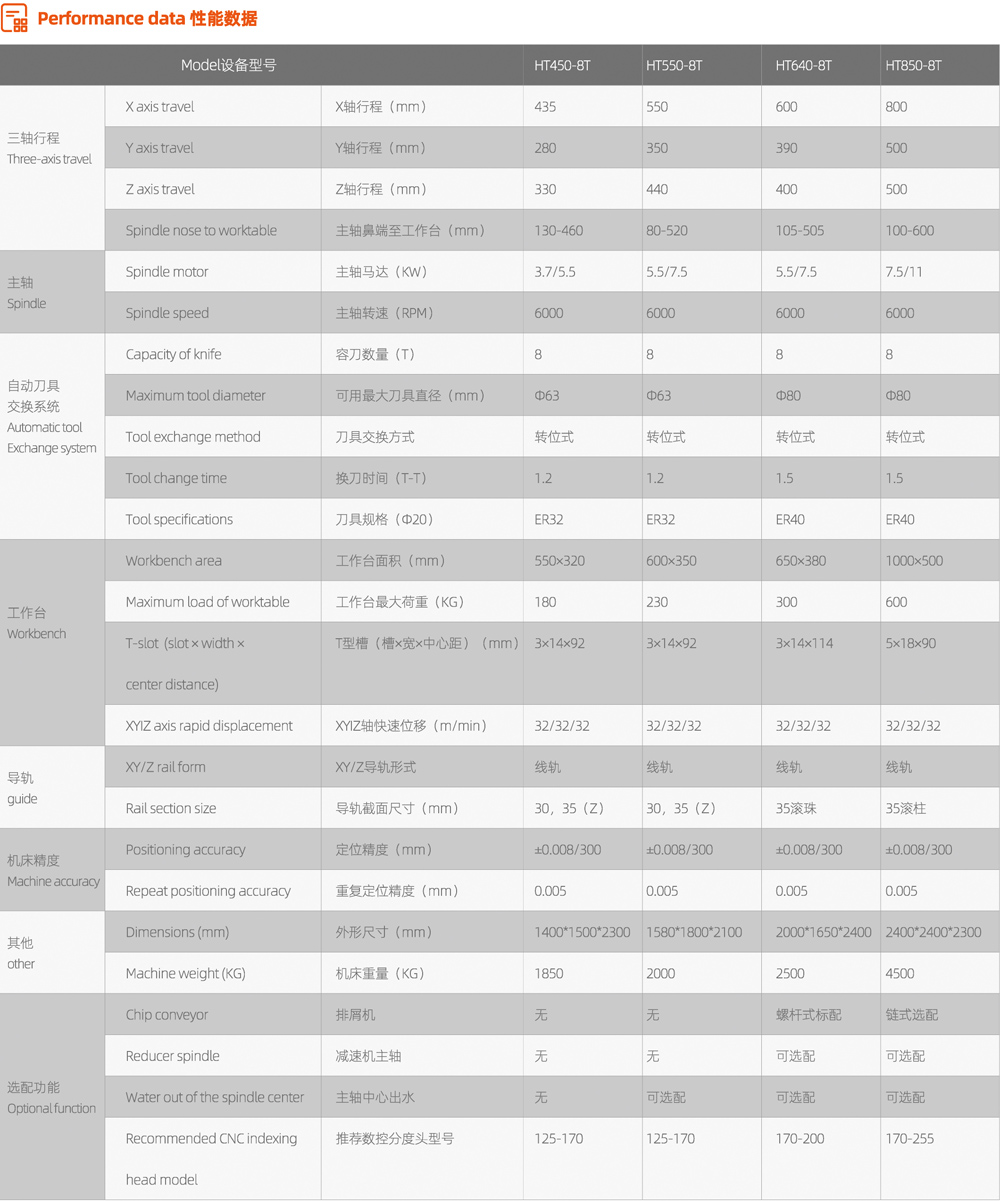

This machine tool is designed and manufactured with high-grade cast iron and box structure.It is properly annealed to eliminate internal stress.The material is tough.In addition to ther box structure design and high rigid body structure,the machine has sufficient rigidity and strength.Demonstrates the characteris-tics of high cutting ability and high reproducibility.

All three axes adopt high-precision precision ball screws,with the pre-tensioning design of the supporting seats at both rends,which can eliminate the transmission backlash and pre-compensate the error caused by the temperature rise to ensure the positioning accuracy.

Spindle motor:This machine uses a high-speed servo motor,and the motor is guaranteed for 1 year free of charge,which makes this machine perform verywell in high-speed,low-speed,light and heavy cutting.

Spindle head:high-precision,high-rigidity international standard ER shaft head,which can withstand high-speed and high-preci-sion cutting of radial and axial loads,and can maintain high precision in machining.

Electrical box:The electrical box is equipped with a heat exchanger for easy heat dissipation to ensure the stability of the system.The external wiring part has a protective coil,which can resist heat,oil and water,

Lubrication system:The automatic depressurization lubrication system of this machine provides centralized oil supply,and the advanced depressurization intermittent oil supply system provides timely,appropriate amount of oil for each lubrication point in a timed,quantitative,constant pressure,and individual manner to ensure that each Lubricating oil is obtainedat the lubrication position in time,so that the machine can operate for a long time without worrying about it.

Machine overall layout and purpose

The main rigid processing,knife tower patent products,quick,the main steel parts,aluminum parts,copper parts,castings and other main punching teeth and other advantages are very obvious.

Industry customers,product style is basically fixed,large volume.

High output of customers,because our machine tool efficiency than processing center higher,rigid than the traditional dniling better,the greater the scale of customer production,the more can reflect the value of our machine tools(knife change time is sharply shortened).For the traditional driling and tapping miling process to play the effect of machine changer and shorten the process of operation.

Mutti-process integration processing,to achieve lean production,pptimize production management.